Uart Display Module

Chip On Glass

Chip-on-board

COB (Chip-on-board) is an integrated circuit packaging technology that connects the Chip directly to the surface of the printed circuit Board (PCB), rather than using traditional chip packaging. In a COB package, the chip is exposed on the PCB surface, then wires are used to connect the solder points of the chip to the corresponding locations on the PCB. This packaging technology enables more compact, thinner board designs and improves circuit reliability and durability.

COB technology is often used in applications that require highly at cost, space and reliability, such as LED lighting, sensors, displays and wireless communication devices. Because COB packaging eliminates the package volume in traditional chip packaging, it allows for greater flexibility in miniaturized design. In addition, the COB package can also provide a shorter circuit connection path, reducing the delay of signal transmission, thereby improving performance and efficiency.

Major Partners

Advantages

COB packaging technology has obvious advantages in size, cost, heat dissipation, electrical performance, durability and reliability, making it widely used in many electronic devices.

Compact Size

The COB package allows the chip to be connected directly to the PCB surface, eliminating the need for the shell of a traditional package, thus enabling a more compact board design for space-constrained applications.

Cost Effective

COB packaging eliminates the shell and pins required for traditional packaging, reducing material costs while simplifying the manufacturing process and reducing production costs.

Optimized Heat Dissipation

The chip directly connected to the PCB surface can dissipate heat more effectively, improving the working stability and reliability of the chip.

Electrical Performance Optimization

The COB package eliminates the resistance and inductance of the chip pin in the traditional package, reduces the resistance of the signal transmission path and improves the performance and efficiency of the circuit.

Increased Durability

The chip in the COB package is directly exposed on the PCB surface, reducing the package volume and mechanical stress, thus improving the seismic and impact resistance of the product.

Enhanced Reliability

The COB package simplifies the connection process, reduces the connection point, reduces the failure rate caused by connection failure and improves the reliability and life of the product.

Disadvantages

Despite the many advantages of COB packaging technology, there are some potential disadvantages in terms of repair, testing, welding technology, environmental sensitivity, design limitations and reliability, which need to be considered and balanced in practical applications.

Difficult to Repair

Since the chip is exposed on the PCB surface, it becomes more difficult to repair and replace the chip in the event of a failure, requiring more sophisticated tools and techniques.

Testing Difficulty

COB packaging hides the internal structure of the chip, making it difficult to carry out comprehensive testing and inspection during the manufacturing process, increasing the difficulty of troubleshooting.

High Welding Technical Requirements

COB package needs to connect the chip welding point to the PCB, the welding technology and process requirements are high, once poor welding may lead to performance problems or failures.

Environmental Sensitivity

The chip in the COB package is exposed and susceptible to moisture, dust and chemicals in the environment, increasing the risk of damage and failure of the chip.

Design Limitations

COB packaging needs to consider factors such as the gap between the chip and the PCB and the coefficient of thermal expansion.The design is complex, which may limit the overall design and performance optimization of the product.

Reliability Affected

The chip in the COB package is directly exposed and vulnerable to mechanical vibration and shock, reducing the overall reliability and durability of the product.

Application

COB screen technology is not only widely used in large display devices but also excels in small screens and compact devices. It is commonly found in smartwatches and wearable devices, offering high brightness, low power consumption, and ultra-high resolution for excellent HD display while extending battery life. In smartphones and tablets, COB screens ensure precise color reproduction and contrast, with a compact design that contributes to a thinner and lighter form factor. Additionally, COB screens are utilized in small appliances and smart home devices like smart speakers and thermostats, providing clear status indicators and control interfaces.

In automotive displays, as well as virtual reality (VR) and augmented reality (AR) devices, COB screens deliver an immersive visual experience with high resolution and fast response times, enhancing readability and overall user experience. In the medical field, COB screens are used in portable devices to offer clear, reliable readings while minimizing power consumption and extending operational life. These applications highlight the importance of COB screens in small devices, offering HD, durable, and energy-efficient display solutions for portable and embedded technologies.

Introduction of FSTN/FTN monochrome blue screen LCD COB display module serial port MPU parallel port 1602 dot matrix LCD

GK POS

Landline Phone

Forehead Thermometer

Punch Clock

Disadvantages

COB Display

Wide Used

Simple Operation

Programmable

Shorten the Customization Cycle

TECHNICAL

SPECIFICATIONS

| Display Font

5*8 Dots |

Display Format

16 Characters*2 Lines |

Storage Temperature

-30℃~80℃ |

| Viewing Direction

6 o’clock |

Control IC

AIP31066,AIP31065 |

Operating Temperature

-20℃~70℃ |

| Input Voltage

4.7V |

Driving Scheme

1/16 Duty, 1/5 Bias |

Power Supply

Single Power Supply(+5V) |

| Model

Sin Yellow Green Transmission Positive |

COB Principle

COB (Chip-on-board) packaging technology is a packaging method that connects the Chip directly to the surface of the printed circuit Board (PCB). The basic principles are as follows:

Prepare the PCB

First prepare a PCB, usually coated with a layer of conductive material on its surface for connecting the chip.

Chip Mounting

The chip is placed in a reserved position on the PCB surface and a conductive glue or welding technology is used to fix the chip to the PCB.

Welding Connection

The welding point of the chip (bond pads) is connected with the corresponding bond pads on the surface of the PCB using welding technology. This usually involves coating the PCB with solder paste, then placing the chip on it and melting the solder paste by heating it to form a welded connection.

Package Protection

A layer of protective packaging material can be applied around the chip or over the entire PCB surface to protect the chip and connection lines from mechanical damage or environmental impacts.

In general, COB packaging technology achieves a simplified packaging process by connecting the chip directly to the PCB surface, improving the integration and reliability of the circuit. It is suitable for applications with high requirements of size, cost and performance requirements, such as LED lighting, sensors, displays, etc.

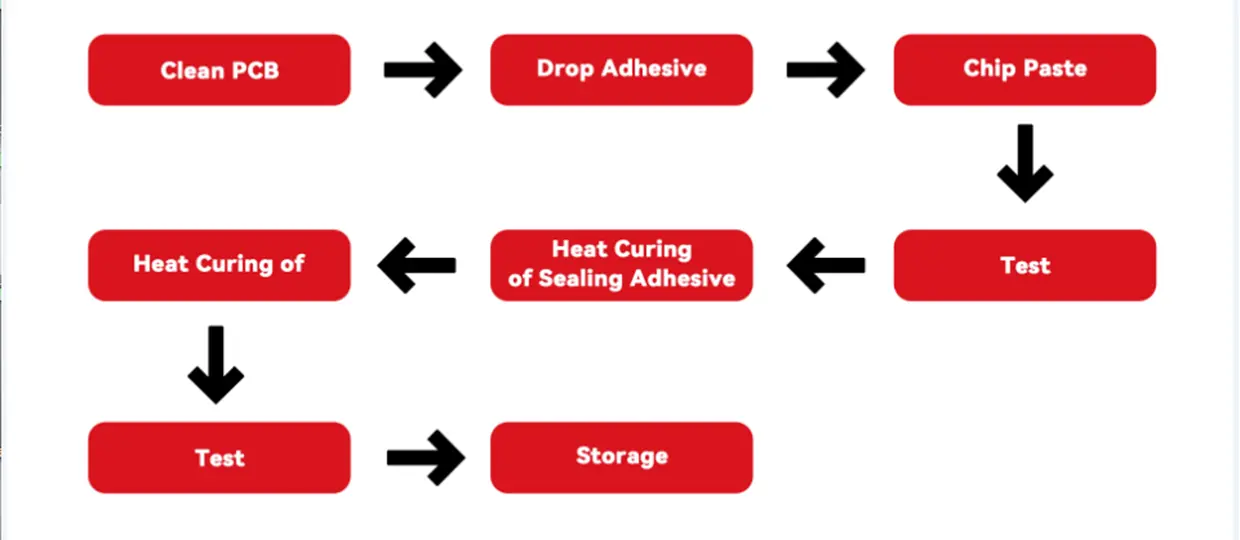

COB Process Flow

In addition, we can provide a variety of COB products with different parameters according to your requirements. Whether you need a specific size, power, operating frequency or other customized requirements, we can meet your needs. We have a professional team and advanced production equipment, can flexibly customize various specifications of COB products, to ensure product quality and performance to meet your expectations.

Tell us what you need

15 years of production experience.Production and independent development capabilities.

Support sampling and customization

Customized according to demand

Professional customer service team

Provide professional solutions

Short delivery time

Advanced production equipment

Source factory

Super affordable price

After-sales service

Good after-sales team

Get Started with Kaihang Display

Our engineering LCD design team is dedicated to promptly reviewing your information, identifying any gaps, and providing you with an accurate quote tailored to your specific display requirements. Simply fill out the form below or reach out to us via email.