VA LCD

PMOLED

AMOLED

Transforming Displays with

Brilliance and Innovation

AMOLED (Active Matrix Organic Light-Emitting Diode) is a type of display based on organic light-emitting diode technology. It uses an active matrix driving method to control pixels, and each pixel is controlled by an independent thin-film transistor. As an advanced display technology, it has excellent display effects and broad application prospects. Its self-luminescence, high contrast, fast response and other characteristics make it widely used in the field of electronic products and become one of the mainstream display technologies.

Major Partners

Structure

The structure of AMOLED includes key layers such as cathode, organic light-emitting layer, electron transport layer, hole transport layer, anode, etc. Among them, the organic light-emitting layer is the key part of light emission, and the thin film transistor is used to control the light emission of each pixel.

Features

Self-luminescence

AMOLED is a self-luminous display technology, where each pixel can emit light independently without the need for a backlight. This enables it to achieve true pure black and high contrast, with a clearer and more vivid display effect.

Fast Response

AMOLED has a fast response speed, which enables high refresh rates and smooth dynamic display effects. This makes it suitable for high-speed content such as watching videos and playing games.

Wide Color Gamut

AMOLED can achieve wider color gamut coverage and more saturated color performance, making the image display more realistic and rich.

Flexible and Curved Display

Since AMOLED is made of organic materials, it can be made into flexible displays, which are suitable for some special application scenarios, such as wearable devices, curved displays, etc.

Low Power Consumption

In static display mode, AMOLED can achieve lower power consumption because pixels only consume energy when they change. This makes it suitable for scenarios that need to display static content for a long time, such as digital clocks or small information displays.

High Cost

Compared with some other display technologies, AMOLED has a higher manufacturing cost and a more complex manufacturing process. However, with the advancement of technology and the play of economies of scale, its cost is gradually decreasing.

Short Lifespan

AMOLED’s organic light-emitting materials are easily affected by factors such as oxidation, moisture, and ultraviolet rays, so their lifespan is relatively short and problems such as color drift or brightness decay may occur.

Color Saturation

VA screens generally have good color depth and saturation, making the color display richer.

Slow Response Time

Compared with TN panels, VA screens have a slower response time, which may cause ghosting in fast-moving pictures

Price and Performance Balance

VA screens are generally between high-end IPS screens and low-end TN screens in terms of price and performance, providing users with a middle option.

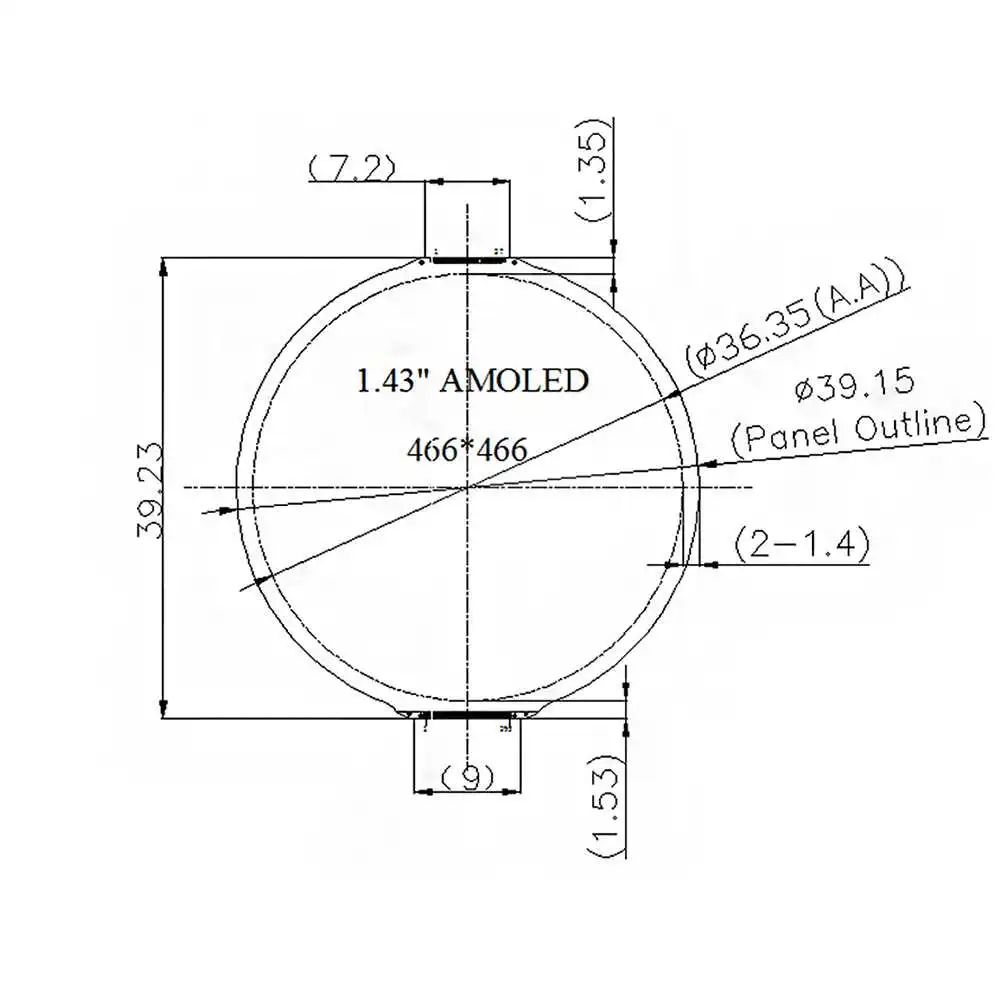

Here is Product Introduction of 1.43-inch AMOLED, Which are Mainly Used in Round Watches.

| Size

1.43 inch |

Resolution

466*466 |

Touch Panel

On Cell |

Outline Dim

39.15*39.22mm |

| COG or COF

COF |

Interface

SPI, QSPI, MIPI |

Active Area

Φ36.348mm |

Working Temperature

-40°C-70°C |

Manufacturing process

The production process of AMOLED includes many cutting-edge technologies in the display panel industry. The manufacturing process can be mainly divided into the backplane section, evaporation packaging section and module section.

The backplane section process forms an LTPS (low-temperature polycrystalline silicon) driving circuit by film formation, exposure, etching and superposition of film layers of different patterns and materials, which provides lighting signals and stable power input for light-emitting devices. The micron-level process precision and the extremely high uniformity requirements for electrical indicators are the technical difficulties of this part of the process.

Organic light-emitting materials and cathode materials are evaporated on the backplane through a high-precision metal mask (FMM), combined with the driving circuit to form a light-emitting device, and then packaged in an oxygen-free environment for protection. The alignment accuracy of the evaporation and the airtightness of the package are both challenges in this process.

Here is product introduction of 2.08-inch AMOLED, which is mainly used in smart watches.

| Size

2.06 inch |

Resolution

410*502 |

Touch Panel

On Cell |

Outline Dim

34.83*43.48mm |

| COG or COF

COF |

Interface

QSPI, MIPI |

Active Area

32.38*37.92mm |

Working Temperature

-40°C-70°C |

AMOLED Evaporation Packaging Process Flow Chart

Since OLED has the good characteristic of self-luminescence, after cutting, panel testing, bias pasting and IC+FPC binding, it directly enters the TP attachment and module testing stage.

The quality control of AMOLED products needs to be comprehensively considered from multiple aspects, including raw material selection, manufacturing process control, process parameter monitoring, product inspection and testing, establishment of quality management system, and customer feedback and improvement, to ensure the production of high-quality AMOLED products.

Raw Material Selection

Selecting high-quality raw materials is crucial to the production of high-quality AMOLED. Raw materials include substrates, transparent electrode materials, thin-film transistor materials, organic light-emitting materials, etc. Our factory cooperates with reliable suppliers to ensure the quality and stability of raw materials.

Manufacturing Process Control

In the manufacturing process of AMOLED, each link needs to be strictly controlled, including thin-film transistor preparation, organic light-emitting layer deposition, encapsulation, etc. Ensure that each step meets the set process parameters to avoid impurities, defects or non-uniformity.

Process Parameter Monitoring

Real-time monitoring and control of process parameters, such as deposition speed, temperature, humidity, etc. Use sensors, monitoring equipment and automatic control systems to monitor key parameters in the production process and adjust them in time to ensure stable product quality.

Product Inspection and Testing

Comprehensive inspection and testing of the produced AMOLED products, including appearance inspection, electrical performance testing, pixel brightness uniformity testing, etc. Filter out qualified and unqualified products through equipment and manual inspection.

Quality Management System

Establish a sound quality management system, including ISO9001 and other certification systems. Formulate relevant quality standards, processes and procedures, and conduct continuous internal audits and improvements to ensure the stability of the production process and the controllability of product quality.

Customer Feedback and Improvement

Collect customer feedback and opinions, and handle customer complaints and quality issues in a timely manner. By analyzing customer feedback and product returns, continuously improve product design, manufacturing processes and quality control systems to improve product competitiveness and user satisfaction.

Application Scenario

AMOLED (active matrix organic light-emitting diode) displays are widely used in a variety of application scenarios due to their high contrast, vivid colors, and low power consumption

Smartphones and Tablets

AMOLED screens are widely used in smartphones and tablets, allowing users to enjoy clearer and more colorful images and videos.

TVs and Monitors

AMOLED technology has begun to be used in TV and monitor manufacturing, which provides better image quality and wider viewing angles.

Wearable Devices

Due to the low power consumption and flexible design of AMOLED screens, they are widely used in smart watches, health trackers, and other wearable devices.

Automotive Displays

AMOLED displays are used in car interiors for infotainment systems, instrument clusters, and navigation systems, providing a clearer and more vivid visual experience.

Virtual Reality and Augmented Reality

AMOLED screens are used in virtual reality head-mounted displays and augmented reality devices to provide users with a more immersive experience.

Medical Devices and Industrial Applications

AMOLED displays are also used in medical devices, industrial control panels, and other professional applications, and their high contrast and viewing angle performance make them very useful in these applications.

Get Started with Kaihang Display

Our engineering LCD design team is dedicated to promptly reviewing your information, identifying any gaps, and providing you with an accurate quote tailored to your specific display requirements. Simply fill out the form below or reach out to us via email.