Chip-on-board

STN LCD

Chip On Glass

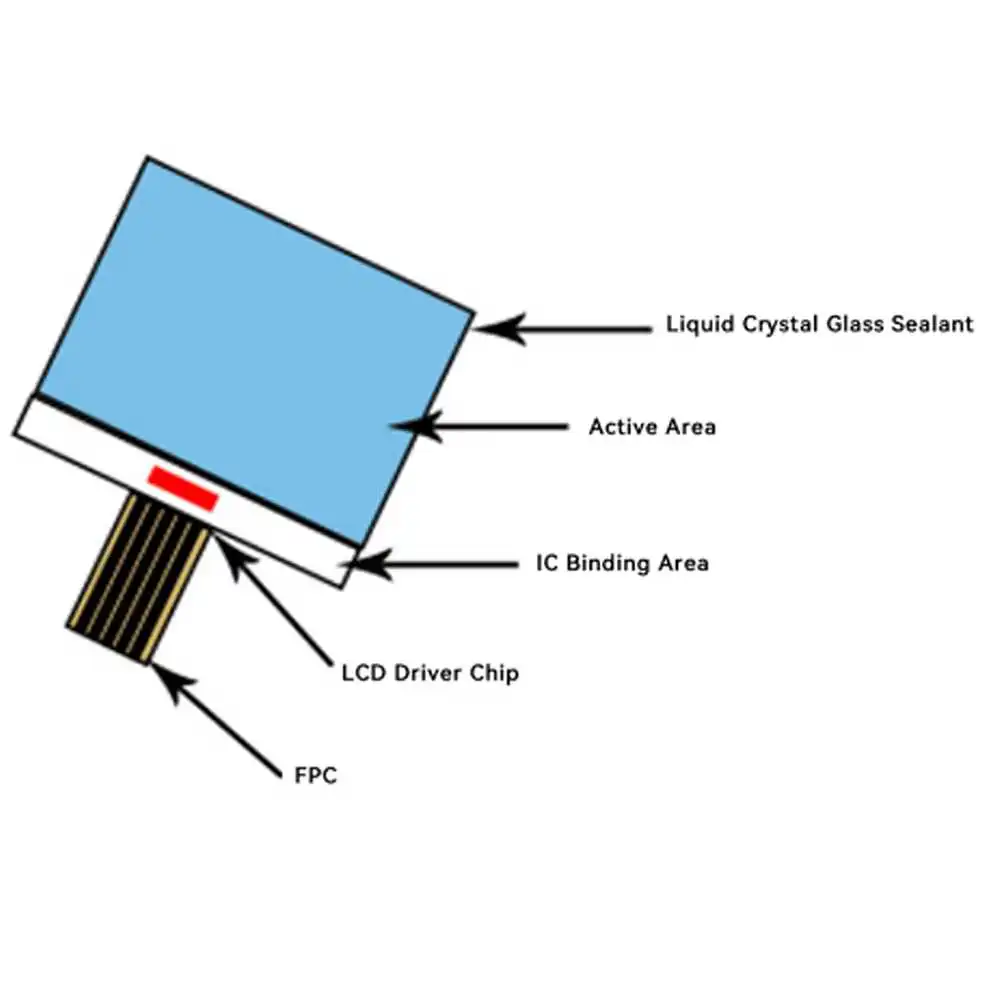

COG packaging technology full named chip on glass, as the name suggests,it is the chip packaging technology on glass. It directly encapsulates the driver IC on the liquid crystal glass through the anisotropic conductive adhesive (ACF) and realizes the driver IC conductive convex point and the ITO transparent conductive pad on the liquid crystal glass, so as to realize the lighting of the screen.

Major Partners

COG Packaging Technology

For designers of industrial displays, in-vehicle displays and portable devices, LCD screens with COG packaging technology own many advantages over traditional packaging. Compare COG technology with traditional packaging technology, the difference between the two is clear. COG display modules are thinner, have higher reliability, offer customers a flexible design and more cost effective.

Liquid crystal display is usually presented in the form of liquid crystal display module.Its built-in driver circuit is easy to install and has high reliability. However, adding the driver circuit of the traditional package to the LCD module will also lead to some disadvantages.For example,it might increase the thickness of the display,costs and the failure rate of the LCD module.

All of these drawbacks are important considerations when it comes to the display of industrial, vehicle and portable devices. This is why designers in these areas should strongly recommend LCD modules with COG packaging technology. COG display modules have a very thin form factor, high reliability and reasonable cost price.

In a traditional LCD module, the driver IC is mounted on a PCB at the rear of the LCD module. As a result, the overall thickness of the display has more than doubled. The driver IC is connected to the PCB with a fixed pin and since LCD typically require many drive inputs (even with multiplex drive technology), the quality of these fixed pins is a key factor in determining the reliability of the liquid crystal product. Moreover, with such a traditional packaging method, the driver IC is exposed to the air and is greatly affected by the environment.

In contrast, the COG display module installs the driver IC directly on the overlapping edge of the LCD glass.It is less than 3 mm thick and all connections from the driver IC to the LCD module are completely isolated from the environment. With COG packaging technology, only one binding is required for each driver IC connector, which ensures optimal module reliability.

Manufacturing

Process of COG

Packaging

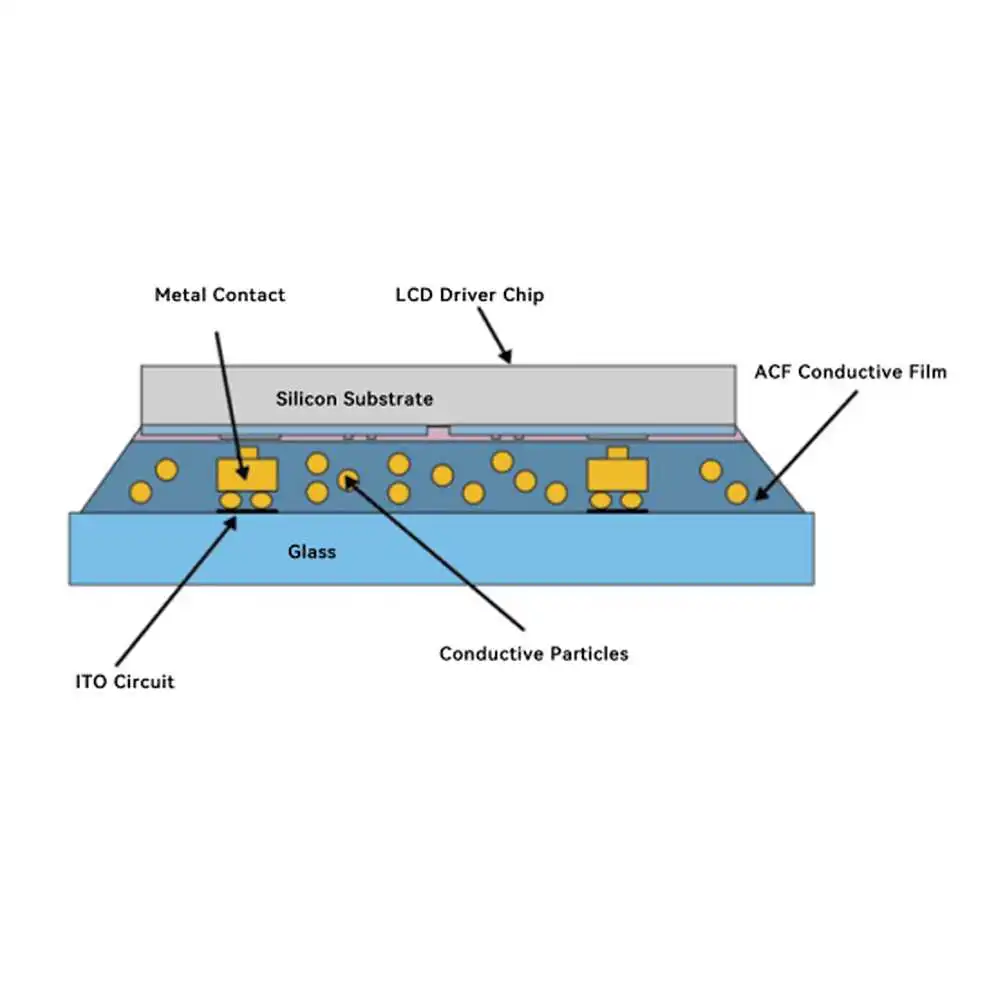

In the COG display module, one of the two glass substrates that make up the LCD module is extended to make room for the installation and connection of the driver IC. Same as traditional packaging, the ITO (indium tin oxide) electrode pattern is created on the surface of the glass substrate. In COG-packaged displays, these electrode patterns are extended to the connection tracks used to drive the IC. To operate stably, the connector track resistivity connected to the driver IC must be lower than the ITO connection resistivity used within the liquid crystal cell. In order to realize the ACF binding technology, there are gold bumps on the connection pad of the driver IC. The connection between the driver IC and the glass substrate is also formed by the ITO and it is recommended to use a wide track for low impedance. The tracks to the display can have a higher impedance, but to achieve the ideal balance, they should be exactly the same impedance.

Binding of Driver Chip and ACF

For the composition of the COG display module, three components are required, as shown in the figure: the LCD panel, the driver IC and the ACF (connection medium).

ACF consists of an epoxy resin (similar to UV-UV-curable glue) containing conductive particles. The conductive particles ensure the contact between the gold bump of the driving IC and the ITO conductor on the glass. The fixation of ACF glue establishes the necessary pressure between the chip and the liquid crystal glass to ensure a good electrical connection between the bumps and the tracks on the liquid crystal glass. Due to the surface tension of the glue on the conductor bead, there is no horizontal contact between the conducting particles, thus avoiding a short circuit between the adjacent gold bumps that drive the IC.

Introducing 3.5-inch TFT LCD Display with a Resolution of 320*480 for Handheld Devices COG Products

TECHNICAL

SPECIFICATIONS

| Model

KH035 Series |

Color

262K,60%,NTSC |

Touch Panel

Accept Customization |

| Size

3.5 inch |

Voltage

1.8/2.8V(TYP.) |

Working Frequency

60Hz |

| LCD Type

TFT |

Back Light

LED |

Brightness

250/300/450cd/m’,etc. |

| Contrast

500:1(TYP.)(TM) |

Interface Spec

45 pins FPC |

Operating Mode

TN, Normally White |

| Active Area

48.96*73.44mm |

Back Light Life

>30.000h |

Operating Temperature

-20° C~70° C |

| View Angle

70/70/70/60 |

COM Interface

CPU/RGB/SPI |

Storage Temperature

-30° C~80° C |

| Resolution

320*480,etc |

Outline Dim

55.26*84.69*2.3mm |

COG Module

Backlight System

The rear side of the COG display module polarizer for display has a reflective coating to match the desired lighting mode:

Reflective Mode

Continuous reflective coating allows viewing in ambient light

Transmission Mode

The back polarizer is transparent and the display must be illuminated from behind.

Semi-reflective Translucent Mode

A thin reflective coating provides enough reflection for the observation of ambient light and allows for use under backlight, so the display can be used in dim conditions.

For transmissible and semi-reflective translucent mode displays, the following backlighting systems can be used:

LED Backlight

Several LED units are installed in a flat box that includes a light guide plate that distributes light evenly across the display. LED backlights come in a variety of colors to produce a bright display while providing low DC current. They have a very long service life.

The above is a demonstration of some of the products. Common screen sizes for COG products range from 0.96 inches to tens of inches and even larger. If you have any demands, whether related to dot matrix display, segment code display or other areas, we can provide professional solutions. Please feel free to contact us, we are committed to providing you with high quality products and excellent service to meet your demands and achieve your goals. Look forward to working with you!

Tell us what you need

15 years of production experience.Production and independent development capabilities.

Support sampling and customization

Customized according to demand

Professional customer service team

Provide professional solutions

Short delivery time

Advanced production equipment

Source factory

Super affordable price

After-sales service

Good after-sales team

Get Started with Kaihang Display

Our engineering LCD design team is dedicated to promptly reviewing your information, identifying any gaps, and providing you with an accurate quote tailored to your specific display requirements. Simply fill out the form below or reach out to us via email.