Infrared Touch Screen

The Paper-Like Technology Reshaping Modern Visual Experiences

Resistive Touch Screen

Reliable and Cost-Effective Touch Technology

Overview

Resistive touch screens are made of two layers of transparent conductive material, one on top and the other on the bottom, with a tiny gap between them. When a user touches the screen with a finger or stylus, the top conductive layer presses against the bottom conductive layer, forming a circuit. The controller measures the resistance value of the circuit to determine the touch location. Resistive touch screens have a simple structure and low manufacturing cost, are suitable for a variety of environments, and are sensitive to the pressure of the touching object.

Major Partners

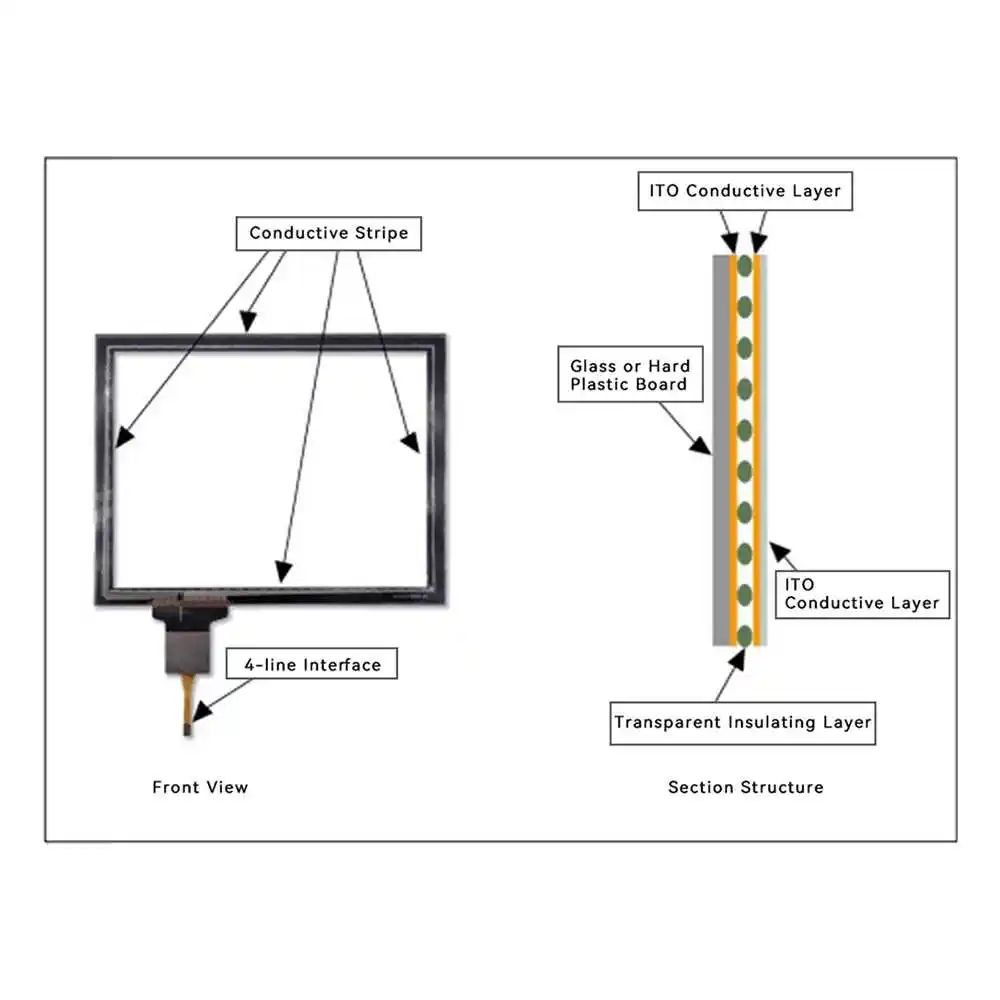

Component

Two Layers of Transparent Conductive Film

The surface of the touch screen is a layer of transparent conductive film, and underneath is another layer of transparent conductive film. The two layers of conductive film are separated by an insulating layer.

Transparent Substrate

The conductive film is attached to the transparent substrate to provide structural support

Four Frames

The frames fix the touch screen and are connected to the control circuit

Advantages and Disadvantages

Resistive touch screen has a simple structure, consisting of two layers of transparent conductive material, which is easy to manufacture and maintain. It is sensitive to touch pressure and can be touched with fingers, gloves or other conductive objects. Therefore, it can adapt to various environments, including indoor and outdoor use and use in harsh conditions. The manufacturing cost of this touch screen is relatively low, which is suitable for cost-sensitive application scenarios. In addition, since it has no moving parts, it has high reliability and durability, suitable for long-term use.

However, resistive touch screens have low sensitivity, slow response speed, and are susceptible to scratches and contamination. Because the surface is a compressible material, it is easily affected by external factors. In addition, most resistive touch screens only support single-point touch, not multi-point touch, so there may be limitations in application scenarios that require multi-point interaction.

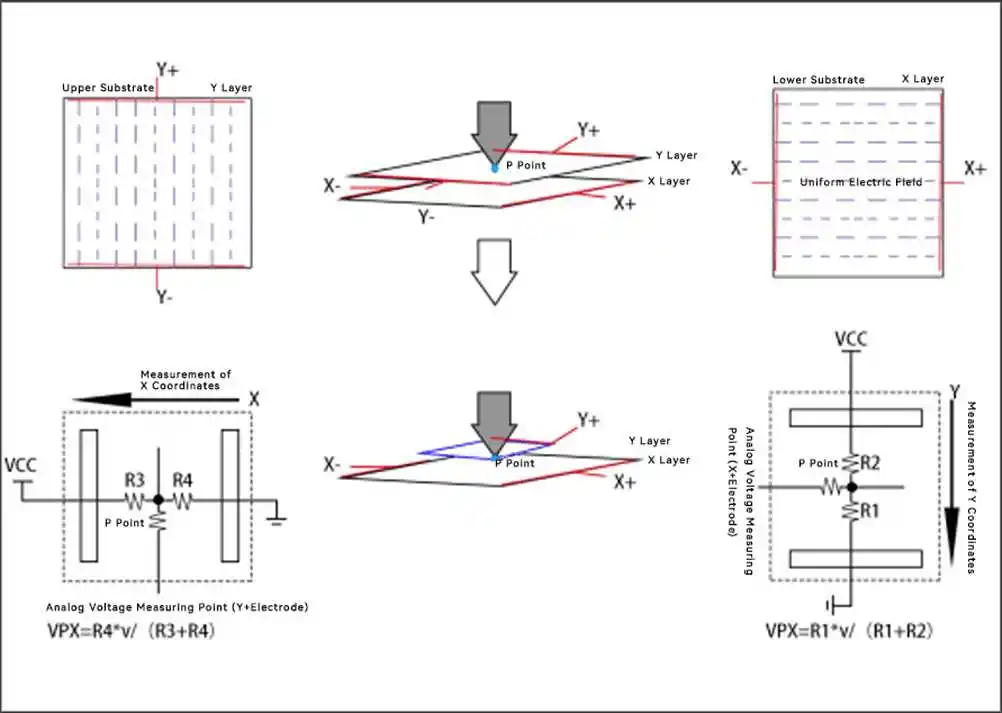

Working Principle

Take the four-wire resistive screen as an example. It is mainly composed of two layers of thin films coated with ITO. One layer has a vertical conductive strip on the left and right edges of the screen, and the other layer has a horizontal conductive strip on the top and bottom of the screen. As shown in the figure below:

If you apply voltage to two conductive strips on a layer of film, a uniform electric field will be formed on the ITO coating. When the user touches the touch screen, the two layers of film at the touch point will come into contact, and the voltage value of the contact point can be measured on another layer of film.

During actual measurement, the control circuit alternately applies voltage to the X and Y electrodes, and then measures the voltage of the other electrode to calculate the coordinates of the contact point.

Working Principle Advantages

The working principle of resistive touch screen has the following advantages:

High Accuracy

Resistive touch screen can achieve high accuracy and can detect the coordinates of the touch point.

High Reliability

The structure of resistive touch screen is relatively simple, stable and reliable, and has a long service life.

PRODUCT CHARACTRISTICS

Low Cost

Strong Adaptability

Strong Durability

High Response Sensitivity

Working Principle Limitations

The working principle of resistive touch screens also has some limitations:

Reduced Light Transmittance

Since there is a conductive film on the surface of the touch screen, it will have a certain impact on the display effect, and the light transmittance is relatively low.

Low Sensitivity

Compared with other touch screen technologies, resistive touch screens have relatively low sensitivity and may require a larger touch force to trigger

Application

Automatic Ticket Vending Machine

When it comes to automatic ticket vending machines, people who travel frequently or on business trips will not feel unfamiliar with them, because now many train stations and bus stations are equipped with automatic ticket vending machines. The screens of such devices generally use touch screen technology, which not only makes the operation process more convenient, but also can meet the needs of use. It is favored by passengers and has the advantages of saving worry and effort.

Production Workshop Equipment

Resistive touch screens are widely used in production workshop equipment. When many young people go to big cities to find jobs, they will choose to enter electronics factories or garment factories. In the production workshops of these factories, many advanced equipment and instruments are used. The use of touch screen equipment is very wide and can meet various application needs.

Catering Ordering System

Resistive touch screens have been widely used in restaurant ordering systems. Many people like to eat Western food or fast food. People who carefully observe the restaurant environment and equipment can find that the restaurant’s ordering system uses touch screen technology, which can optimize the diners’ dining experience, realize multiple ordering functions in a short time, and simplify the dining process.

Resistive touch screens can also be used in medical equipment, machine tool control equipment, etc. The purchase method of this type of product is relatively simple. First, you need to determine the actual use, then contact the manufacturer, and then pay for the purchase.

If you have any needs, please contact us, we will provide you with a full range of technologies and services.

We mainly provide personalized customization services, and can customize resistive touch screens of various sizes according to your needs. Whether you need a small touch screen for a portable device or a large touch screen for an interactive display, we can meet your needs. Our customization services cover material selection, production and quality control, ensuring that we provide you with high-quality customized products.

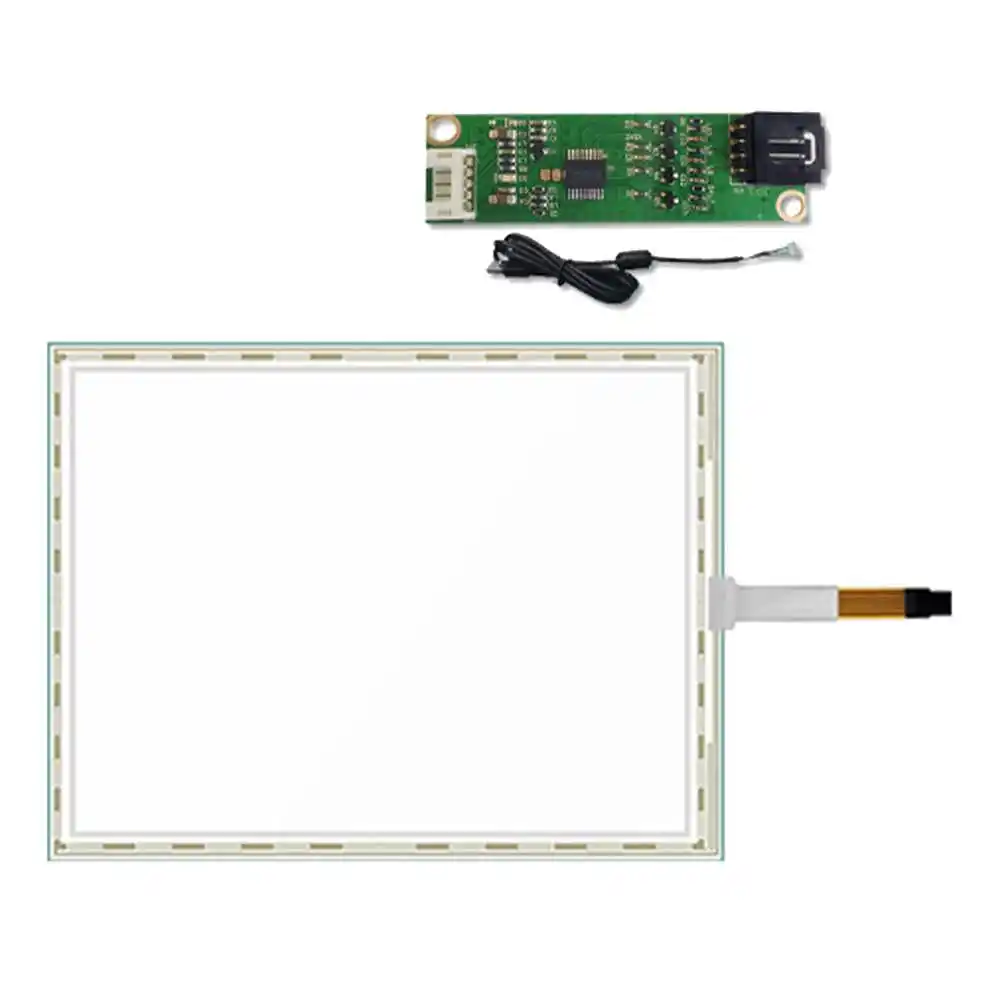

Here is the Product Introduction of a 15-inch

| Screen Size

15 inch |

Contact Type

Single Touch |

Outline Dimension

347.6*274.9mm |

| Wire Length

99mm |

Transmittance

≥80% |

Controller Status

Split Typ |

| Wire Position

3 o’clock |

Aspect Ratio

4:3 |

Simul. Contact

Single Touch |

| Active Area

303*227.5mm |

Operating Tem.

-10°C~ 60°C |

Appearance Thickness

2.1mm |

| Storage Tem.

-20°C~70°C |

Controller Interface

I²C, USB |

Get Started with Kaihang Display

Our engineering LCD design team is dedicated to promptly reviewing your information, identifying any gaps, and providing you with an accurate quote tailored to your specific display requirements. Simply fill out the form below or reach out to us via email.